UK Aircraft Engine Specialists

Engine

Overhaul

& Exchange

Comprehensive aircraft engine overhauls, exchange programmes, and dynamometer testing. The only UK engine shop that flies its own engines.

What We Do

Our Services

Engine Overhauls

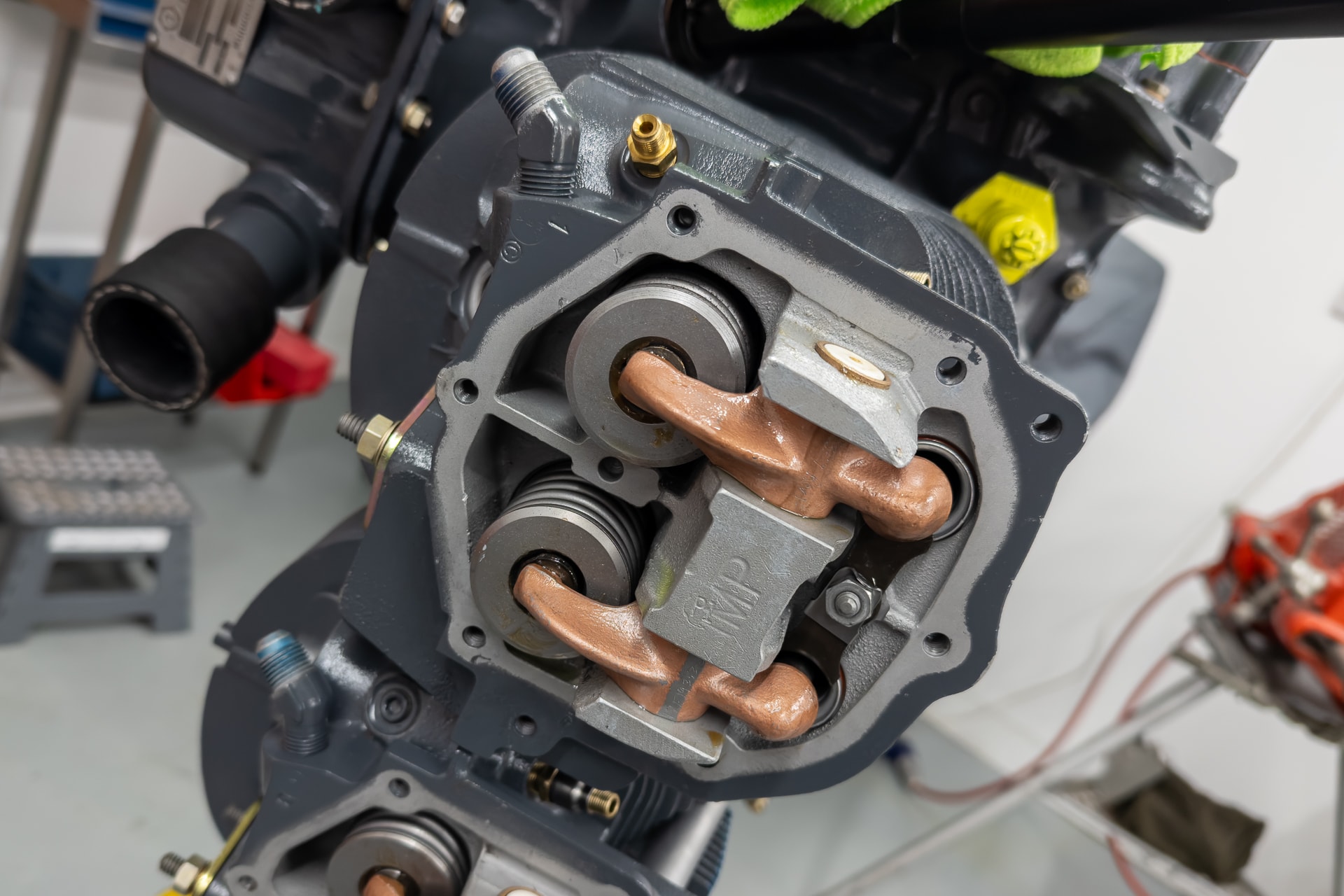

Complete strip-down, inspection, and rebuild to manufacturer specifications. Photographic evidence of every finding.

Engine Exchange

Minimise downtime with our exchange engine program. We offer exchange engines. We provide you with a zero timed engine against a core deposit. We collect your core, strip and inspect it, and refund the deposit less any unexpected component charges. Our stock is constantly changing so please contact in advance.

Dyno Testing

Every engine tested across the full operating range on our dynamometer before release.

Magneto Servicing & Overhaul

Critical magneto servicing and overhaul services. New magnetos supplied as standard with zero-timed engines, with cost-effective overhaul options available for existing units.

Transparent pricing, no shortcuts

Our aim is to build super high quality engines and we don't compete on price. We do however operate completely transparently and you can be absolutely certain you are getting what you are paying for. We employ the best practices both in engine building and in administration and planning. Doing things properly also means efficiently so you can be sure of getting a fast and proper service at a fair price.

experience

Why Choose Us

We are a small artisan engine shop

We are a small artisan engine shop owned by the same shareholder as the British Aviation Academy. We fly engines built by us so we are super focussed on quality but also fast turnaround. Our engineers have been building engines for 40+ years and we send our staff on either Continental or Lycoming factory courses. We have our own computer controlled engine test cell so we can demonstrate the power output. Customers are welcome to visit by appointment and each engine will come complete with documentary and photographic evidence of work done.

Photographic Evidence

Where components are unserviceable, you see exactly what we see. Full documentation, no guesswork.

Owners Welcome

Visit our workshop at any stage of your build. Meet the engineers. Witness our standards first-hand.

Clear Communication

You always know where your engine is in our process, from initial quotation to final dyno test.

Our Build Process

Transparency at every stage

Quotation

Detailed quotation provided subject to physical inspection.

Inspect & Evidence

Full strip-down. Any failed components documented with photographic evidence and options presented.

Approve & Deposit

Scope agreed, deposit collected, precision rebuild begins.

Build & Dyno Test

Meticulous rebuild followed by dynamometer testing across the full operating range.

Collect & Fly

Final payment, engine released. Ready for the air.

The Difference

Built to a standard we trust with our own lives

Warranty on overhauled engines is 24 months or 500 hours whichever comes first. On repaired or shock load/overspeed engines it is 12 months or 250 hours whichever occurs first. Every engine is dyno tested. Every process is documented. Every owner is welcome.

From Our Customers

"They found a worn camshaft, sent photographs, and gave me clear options. That level of transparency is rare in this industry."

They invited me to the workshop to see the engine on the dyno. Watching it run first-hand was extraordinary.

The exchange option meant my aircraft was back in the air weeks sooner than expected.

I visited three engine shops before choosing Aero Engines. The difference was immediately obvious.

Ready to start?

Get a no-obligation quotation or arrange a visit to our workshop.